HD Low Iron Glass

Select Shape

Select Shape

If you need any help from our Experts then please call at +44 20 3885 0857

Low Iron Glass Usage and Applications

HD Low iron glass is a multipurpose glass which is used in multiple applications..

What is the difference between Standard and Low Iron glass?

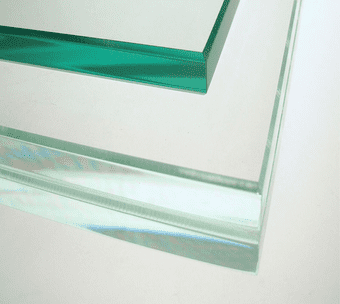

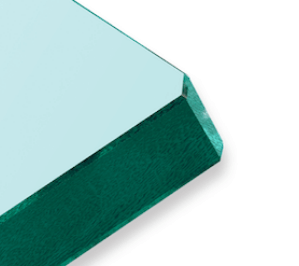

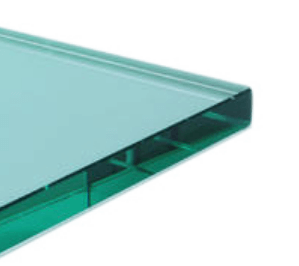

A Low Iron glass differs from a standard glass in a couple of ways. The first and most noticeable difference is clarity. As the name implies, a low iron glass contains a relatively lower concentration of iron as it is made from Low Iron Silica sand along with 0.1% of Ferric Oxide contents. As a result, it is more transparent and does not have the greenish tint on the edges that can be observed in the case of standard glass. The second prominent difference between both these types of glass is light transparency. Compared to standard glass, low iron glass offers a VLT (Visible Light Transmittance) of 91%, making it the best choice when it comes to commercial applications. Moreover, low iron glass offers visibility of actual colors. Its invisible appearance enhances the observer's experience by portraying the exact colors of a particular object, making it the preferable choice for industries to showcase their products.

What is the level of clarity of a Low Iron Glass?

A Low Iron Glass has a Visible Light Transmittance (VLT) of 91%. On the contrary, a Standard Glass has a VLT ranging from 30% to 70% depending upon certain factors.

What are suitable applications of Low Iron Glass?

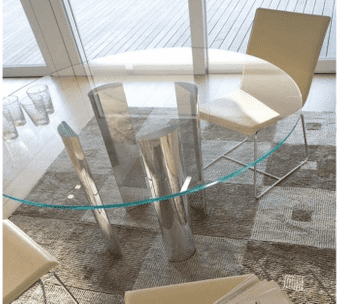

Glass Mirror House offers its customers a variety of shapes, edge types, and sizes that are suitable for multiple applications. Common applications include table tops, shower doors, glass railings, store front doors, and hotel windows.

What are the benefits of Low Iron Glass?

Low Iron Glass is relatively clear and allows high light transmission rates. From enhancing the appearance of your home or office to showcasing your products in their original bright and vivid colors, low iron glass is your best choice.